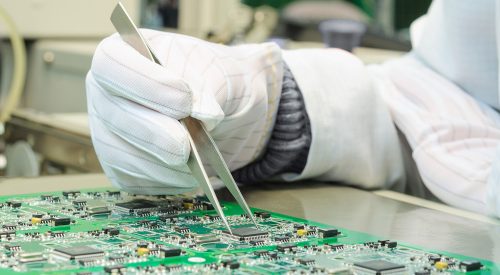

Through Hole PCB Assembly

Through Hole PCB Assembly Expertise

Enhanced Reliability

Through hole technology is the mounting process in which leads are used to connect two locations on a circuit board electrically. This process involves drilling into the printed circuit board to insert the lead through the holes and soldering components on the board using automated soldering or manual soldering methods. Because leads go through the board and are soldered in place, this creates a stronger bond between components and the board, enhancing reliability and durability.

Benefits of Through-Hole Technology

- More resistant to environmental stress

- Highly reliable and durable

- Strength of bonds

- Ideal for larger components that experience high power and high voltage

- Allows room for improvement in prototyping

Industry Leading Experience

Proven To Perform

ThermOmegaTech® puts quality first, meaning that your product outcome will exceed expectations, as every project is handled in a well-defined and strictly controlled environment. Our through hole PCB assembly designs have proven to perform in the most extreme environments, taking ruggedness to a new level.

Ready to Get Started?

Join Our Newsletter

Stay up to date with the latest industry news, product information, case studies & more!