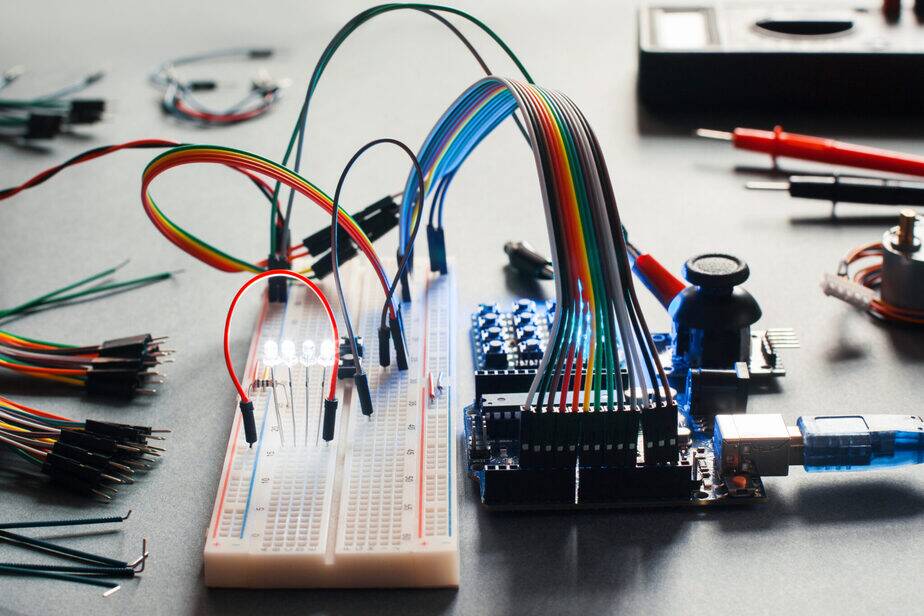

Prototype PCB Assembly

Whether you’re testing the performance of an idea, evaluating room for improvement, or showcasing a new product to investors or at a trade show, ThermOmegaTech® provides accurate and functional prototype representations of your PCB assembly design. Our goal is to solve your prototyping challenges by validating and testing your concepts, helping your customers and investors visualize your product, and beginning the manufacturing process with confidence.

Pre-Production Prototyping

Prototyping allows you to test your PCB design and its performance before moving it into full-scale production. At ThermOmegaTech®, we understand the importance of this step in ensuring a high-quality, functional product. Our PCB assembly prototyping services adhere to your specified design requirements and undergo comprehensive testing and evaluation. We put your prototype through rigorous tests to ensure precise component placement and environmental durability.

Focusing strongly on quality assurance, apparent through our recent commitment to an AS9100D certified quality management system, ThermOmegaTech® has the expertise and equipment to test your PCB design accurately.

Our Prototype PCB Assembly Process

- Design Review and Consultation – Our team will work closely with you to review your design and provide valuable feedback.

- Material Sourcing – We source high-quality materials and components from trusted suppliers to ensure the durability and functionality of your prototype PCB.

- Assembly – We can assemble your designs using surface mount or through-hole technology to meet your project’s needs.

- Quality Control – Every prototype PCB undergoes rigorous testing and inspection, including temperature, humidity, thermal shock, and vibration.

- Packaging – Once your prototype PCBs pass our stringent quality checks, we ensure they are securely packaged and delivered to you.

Decades of Expertise In Full-Service Prototyping

Specializing in prototype PCB assembly and small-volume production, we will explore your concept, uncover any design issues, and generate new ideas to improve design for manufacturability (DFM). Prototyping allows you to engage with your product, fully understand its functionalities, and discover alternative solutions if needed.

ThermOmegaTech’s Prototyping Capabilities:

- Turnkey & Quick Turn PCB Assembly

- Tailored Full System Integration (Box Build Assembly)

- Painting, Coating & Finishing

- Assembly Testing

- Part-fit Testing

- Environmental Testing

Advantages of Prototyping With ThermOmegaTech®:

1. Streamlined Manufacturing Process – Prototyping eliminates the need for engineers to go through several iterations. By creating a prototype, you can get visual aid from clients, and discover design issues quickly, which will minimize the need for rework. This ensures your team has a thoroughly tested and secure PCB assembly before production.

2. Reliable Prototype = Reliable Product – Testing the PCB assembly design, functionality, and resilience to the environment helps you determine how well the finished product will work.

3. Reduces Overall Cost – By enabling designers to examine every detail of the PCB design and its functionalities, prototyping helps them identify and address design flaws before committing to a full production run. In the end, this will save costs and time while reducing the possibility of rework or, worse still, a total redesign of the product.

Proven Performance

At ThermOmegaTech®, we understand the various reasons for creating a prototype of your PCB assembly. Our goal is to see our customers satisfied with their overall product. We are experts at what we do and will go above and beyond to ensure high-performance electronic prototyping and comprehensive testing so that your product is safe, manufacturable, and ready to go to market.

Ready to Get Started?

Join Our Newsletter

Stay up to date with the latest industry news, product information, case studies & more!